R2B Strategies

R2B+P

A Support for Hybrid Management

Hybrid management in various technologies and fields has been key to our growth.

Focusing on the concept of “life science for a healthier planet,”

we drive innovation that uses business at scale to change society.

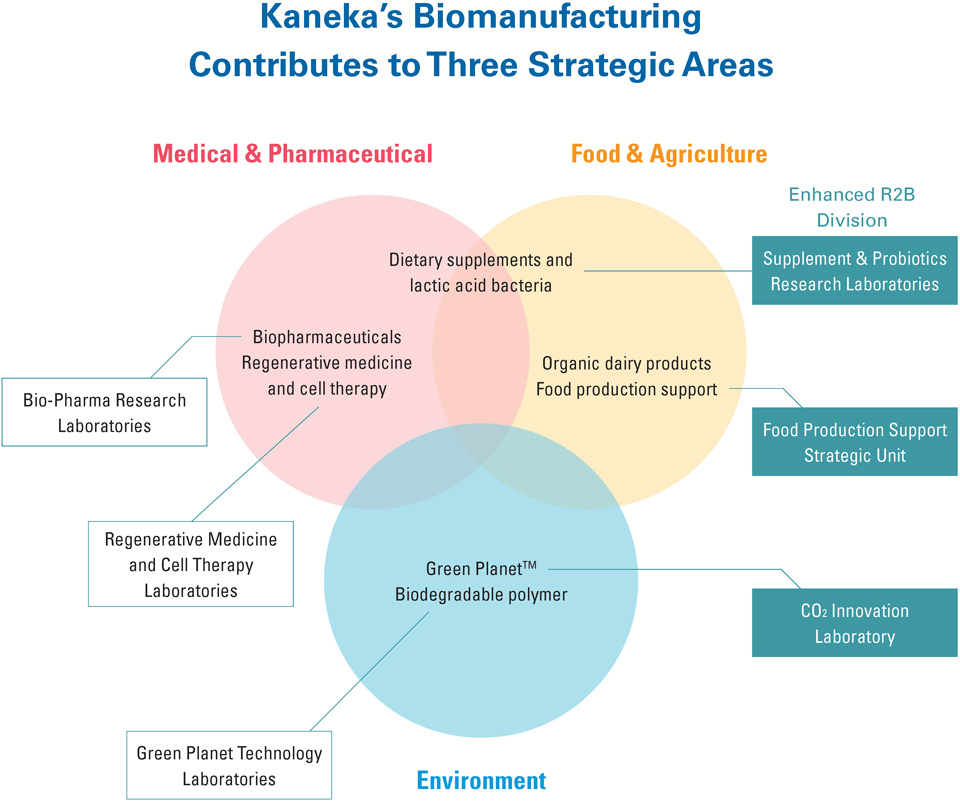

Kaneka’s Biomanufacturing

Kaneka is an advanced biomanufacturing company that started out with technologies for yeast and other fermentation. We have accumulated biomanufacturing technologies that have garnered attention in various fields such as pharmaceuticals,agriculture, and environmental fields.

We are enhancing our R2B system to expand our strengths and accelerate research and development in the life sciences field.

Evolution of Green Planet™ Biomanufacturing Technology

Advances in Green Planet™ Molding Technology

A key challenge in terms of promoting the use of Green Planet™ has been the difficulty in the molding process. Amid developments in cultivation and compounding technology and in processing technology, solutions are now emerging to technical challenges in our functional product groups such as thin-walled deep-drawn blisters, films, and fibers.

Increasing Production Capacity

We have made progress in joint development and product launches with major brand holders in Japan, the U.S., and Europe. Construction of the new 15,000 ton capacity facility at the Takasago Manufacturing Site is progressing as planned toward launch.

We have also begun studies focusing on our next phase of overseas expansion.

Green Planet™ Manufacturing Process Using CO2 as a Raw Material

In our research and development to produce Green Planet™ using CO2 as a direct raw material, we are making progress in developing technology based on gas fermentation. This research and development was selected for the Green Innovation Fund Project promoted by the Japanese government, and we are working toward the construction of a demonstration plant.

Furthermore, we are developing biomanufacturing technology using CO2 as a raw material. We will further accelerate research and development with a view to combining it with our health and food technology.

A Hybrid of Food and Health

Providing Coenzyme Q10 in a Variety of Forms

We are developing new healthy foods by combining our food processing technology with functional food ingredients. “Watashi no Chikara (My Energy)™ Q10 Yogurt” is a food application that combines technologies to enable the intake of coenzyme Q10 in a “reduced form” even in food.

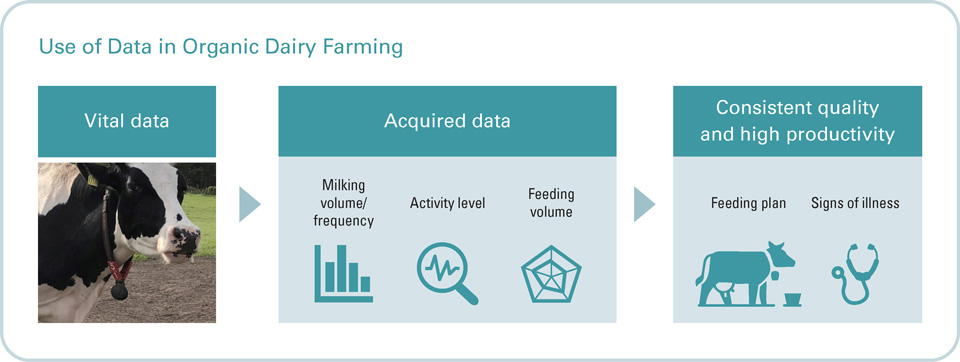

Combining Dairy Farming and Chemistry in a New Organic Dairy Farming Process

At Betsukai Wellness Farm, we are building a new dairy farming process by combining chemical plant operation and design technology with dairy farming.

Positioning the barn as a kind of production plant, we provide an environment that is favorable for the cows. We then use data on each cow to maintain consistent quality and production volume.

Deploying Energy Solutions

Expansion to Diverse Applications

In the photovoltaic business, we offer unique products for the architectural and automotive fields, delivering high-efficiency power generation performance and design characteristics.

Applications of these products to building exterior walls and windows have earned strong recognition for their contribution to mitigating climate change.

Development of Next-Generation Perovskite Solar Cells

To increase power generation performance and expand the range of applications, we are also focusing on developing perovskite solar cells. By combining polymer technology accumulated in the resin area with existing silicon-type solar cell technology, we are also developing tandem products that achieve new levels of high efficiency in electric power generation.

T-Green™ Multi Solar, a photovoltaic power generation system integrated with building external walls and windows, receives the Fiscal 2023 Minister of the Environment Award for Climate Action from Japan’s Minister of the Environment

“T-Green™” is a registered trademark of Taisei Corporation.

(Courtesy of Taisei Corporation)

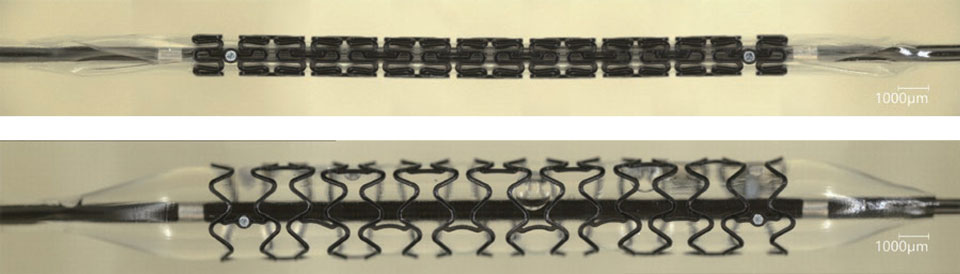

Developing the Medical Device Business through Open Innovation

Our medical device business is backed by best-inclass processing technology. A key strength is manufacturing that targets the precise needs of physicians.

We are combining external technologies and tackling challenges in new areas as we strive to advance solutions to meet growing demand for extending healthy life expectancy.

In the area of catheters for intravascular treatment, for example, we acquired Japan Medical Device Technology Co., Ltd. (“JMDT”), making it a wholly owned subsidiary. By integrating JMDT’s bioresorbable stents technology, we aim to expand our business in the stent treatment area.

Bioresorbable stents developed by Japan Medical Device

Technology Co., Ltd.*

(Above: stent before expansion, below: stent after expansion)

*A stent is a small, expandable, and tubular metal mesh that is used as a medical device to treat narrowed or occluded coronary arteries. A catheter loaded with a stent is transported to the treatment site where the stent is implanted to restore blood flow. Bioabsorbable stents are taken up by the body a certain period of time after implantation, ensuring that they do not interfere with treatment after recurrence.