Manufacturing Strategy

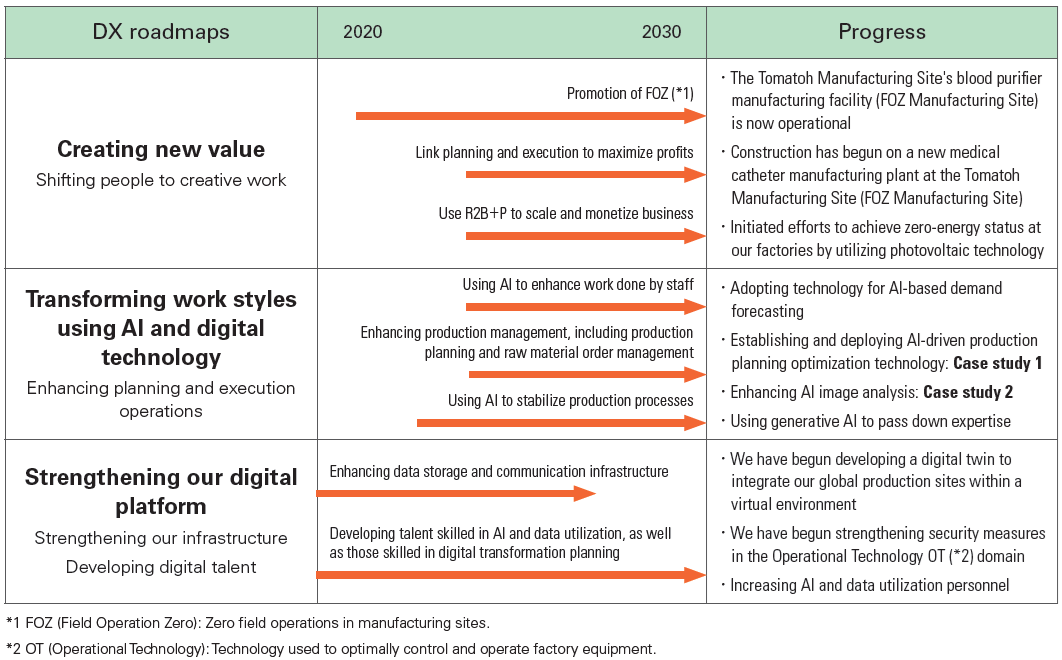

Digital Transformation (DX)

We will transform our production plants into cutting-edge facilities to excel in global competition

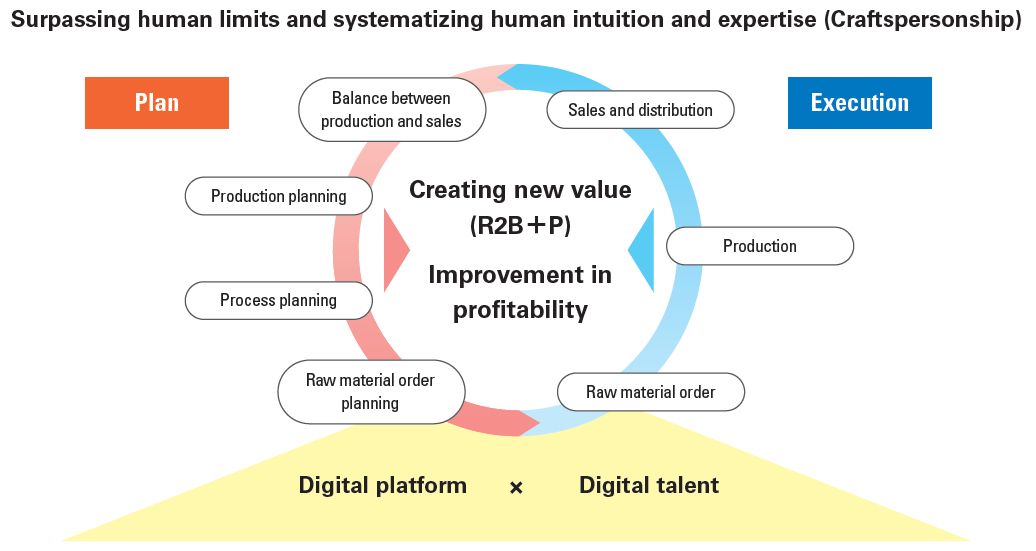

We will leverage AI and digital technology across the entire supply chain, linking R2B, production, and business areas to allow our people to shift toward more creative work.

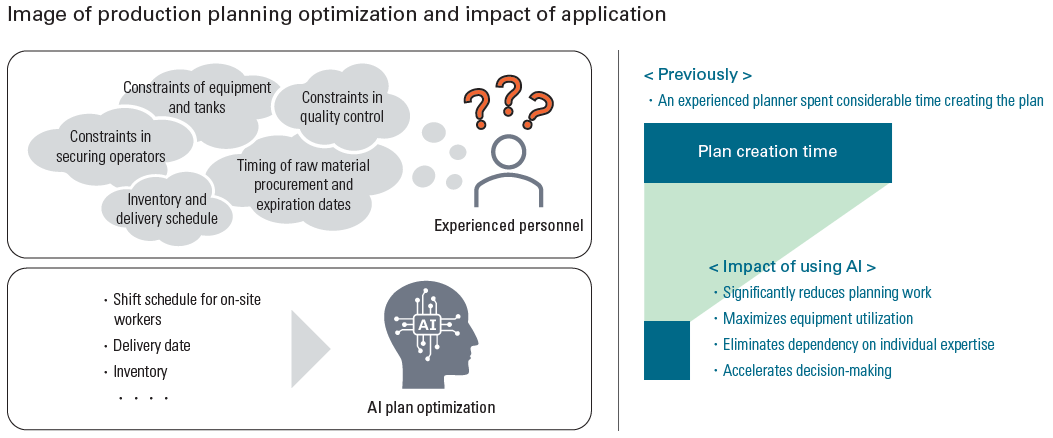

< Case study 1 >

Optimizing production planning with Kaneka’s unique R2B+P approach

Optimizing production planning with Kaneka’s unique R2B+P approach

Creating production plans that consider manufacturing constraints and customer demands previously depended on experienced personnel. However, our R2B team is now closely collaborating with the production site to use AI to automate this work. This initiative focuses on developing AI technology and increasing personnel who can use AI and data. We are also broadening areas of application.

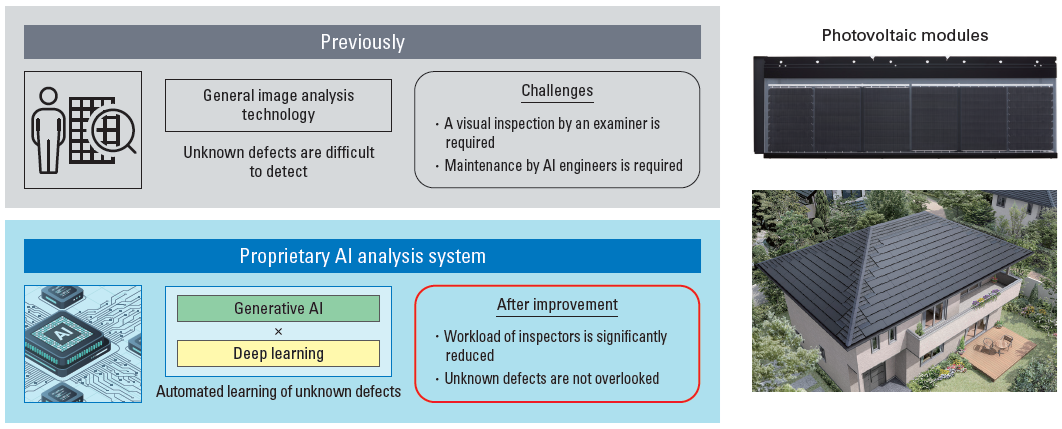

< Case study 2 >

Combining generative AI and deep learning to automate solar cell inspection

Combining generative AI and deep learning to automate solar cell inspection

When inspecting micro-defects in solar cells with established image analysis techniques, maintaining inspection accuracy and detecting unknown defects proved difficult. Through collaborative research with Nara Institute of Science and Technology, we developed a unique AI analysis system that integrates generative AI and deep learning. We have used this innovation to automate our inspection processes. This technology goes beyond traditional deep learning by not relying on past data. It will enhance not only our solar module manufacturing sites, but also drive the realization of FOZ in our production processes.