Manufacturing Strategies

Carbon Neutrality

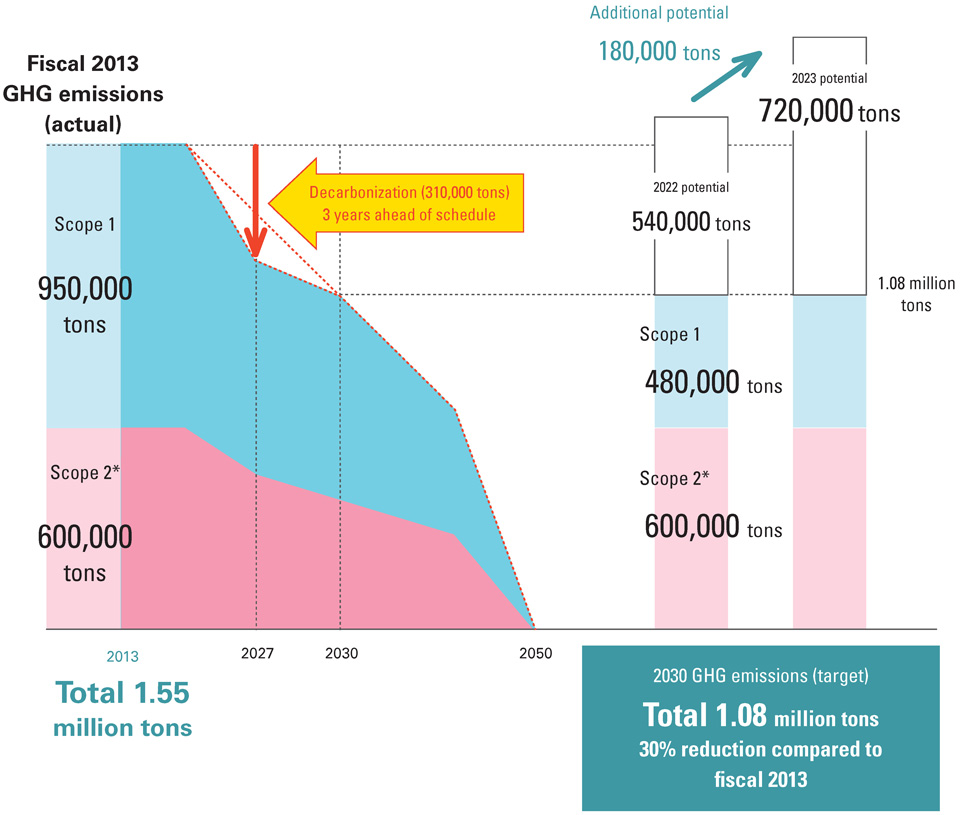

The Kaneka Group aims to reduce Scope 1 and 2 GHG emissions, which include domestic and overseas Group companies, by 30% by 2030 (compared to fiscal 2013) and to achieve carbon neutrality by 2050.

For Scope 1 emissions, we will upgrade our coal boilers to gas turbine co-generation equipment, thoroughly save energy through the efficient recovery of plant exhaust heat, and promote process innovation for energy-intensive equipment.

For Scope 2 emissions, we will promote the use of renewable energy and low CO2 emission factor for electricity.

*Since the CO2 emission factor for electric power companies is subject to change, we expect our emissions to be equivalent to those of fiscal 2013.

Progress to Date - Identifying GHG Emissions Reduction Themes -

In fiscal 2023, we carried out research activities into GHG reduction themes at our domestic and overseas Group companies for the GHG emissions reduction of 30% set in our 2030 target. We expanded our reduction themes, including potential ones, to a cumulative total of 720,000 tons.

GHG Emissions Reduction Theme Potential

| Item | Fiscal 2022 Uncovered potential |

Fiscal 2023 Additional potential |

GHG emissions reduction theme Total potential |

|---|---|---|---|

1) Fuel conversion |

310,000 tons | ― | 310,000 tons |

2) Energy saving |

90,000 tons | 110,000 tons | 200,000 tons |

3)Process innovation |

100,000 tons | ― | 100,000 tons |

4)Use of renewable energy, low CO2 emission factor for electricity and steam power |

40,000 tons | 70,000 tons | 110,000 tons |

| Reducing GHG Emissions Total | 540,000 tons | 180,000 tons | 720,000 tons |

1) Fuel Conversion

We are planning to move our decarbonization ahead of schedule by three years (expecting to achieve it by 2027 instead of 2030).

Takasago Manufacturing Site plans to install a new gas turbine co-generation system in 2027 as part of our decarbonization and GHG emissions reduction measures. In addition, we will, as appropriate, select type of fuel, including non-fossil fuels, and the amount of electricity that we purchase, balancing economic efficiency and environmental contribution.

2) Energy Saving

We investigated the implementation of exhaust heat recovery technology using heat pumps, including at our domestic Group companies. Together with our ongoing energy saving efforts, this has added a potential reduction of 110,000 tons.

3) Process Innovation

The vinyl chloride monomer production innovation pilot will begin demonstrating GHG reductions in 2024. We plan to include the production of Green Planet™ in our uses for hydrogen and CO2 in the production process.

4) Use of Renewable Energy, Low CO2 Emission Factor for Electricity and Steam Power

As a Scope 2 reduction measure, Kaneka Malaysia will switch to biomass-derived steam in 2025. Kaneka Group will expand the installation of inhouse photovoltaic power generation systems on plants and other premises in Japan and overseas as we promote the use of renewable energy. At our overseas plants, we plan to use a low CO2 emission factor for electricity.